In the past 40 years the consumption of energy in India has grown at 6% per annum, but production grew only 4.5% per annum. This shows a huge demand-supply gap and is the reason why India is not able to meet its electricity generation targets. Further compounding the situation are the very large T&D and AT&C losses, increasing fossil fuel prices and stagnant domestic hydrocarbons production in the country.

As per various Power sector studies, energy efficiency stands out as the best option for overcoming the issue of shortfalls in power supply, as one unit of energy saved at the consumption level reduces the need for fresh capacity creation by 2.5 times to 3 times. Further, it has been estimated that nearly 25,000 MW can be saved by implementing end-use energy efficiency and demand side management measures throughout India. Energy conservation potential for the economy as a whole has been assessed as 23% with maximum potential in industrial and agricultural sectors.

The Government of India is aggressively promoting Energy efficiency through the Energy Conservation Act and the National Mission for Enhanced Energy Efficiency, the Energy Conservation Building Code, Performance Contracting (PC) by ESCOs; Standards & Labeling for energy efficient appliances and demand side management programmes.

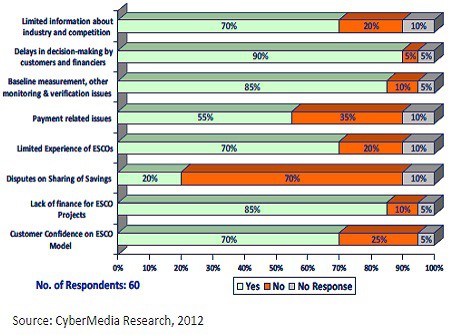

However, in spite of all this awareness, energy efficiency projects are not attaining the desired pace because of challenges present in the current market scenario. In a recent study CyberMedia Research (CMR) pointed out some reasons for the failure of the ESCO industry to take off in the country, but these reasons are applicable to most of the areas related to energy efficiency as mentioned below.

Figure 1. Factors responsible for the below par performance of the India ESCO industry

During the analysis it was observed that baseline measurement and measurement & verification (M&V) have the most impact on energy efficiency projects. Other factors like delays in decision making by clients and financers, disputes in sharing of savings, customer confidence on ESCO or other types of energy efficiency service providers are directly connected to the M&V issue. Client and financers will be interested in the projects if actual achievable savings can be verified by a third party or external expert. Thus measurement & verification becomes the missing link in Energy Efficiency projects.

Measurement and Verification in Energy Efficiency projects: As per Evolution Verification Organization (EVO), M&V is a process of using measurements to reliably determine actual savings created within an individual facility by an energy management programme. Savings cannot be directly measured, since they represent the absence of energy use. Instead savings are determined by comparing measured use before and after implementation of a project, making appropriate adjustments for changes in conditions.

M&V Implications in the India Scenario: M&V process for determination of savings is required for all energy efficiency projects whether commercial, industrial or government. This is because decision makers for implementing any EE project will be interested in a project if the achievable savings are calculated properly. Presently M&V process can be implemented in the areas mentioned below:

- Perform-Achieve and Trade (PAT): Government of India has launched PAT scheme on 1st of April 2012. In this program 478 units from eight energy intensive industries have been identified as designated consumers. These units need to reduce their energy consumption by a certain percentage. M&V process will help to determine the actual savings and the presence of third party M&V professionals would have greater acceptability for the savings achieved amongst the concerned stakeholders.

- Energy Service Companies (ESCOs): The ESCO industry is still in a nascent stage and in year 2010-2011, the revenues of 114 ESCOs accredited by Bureau of Energy Efficiency (BEE) was around Rs. 98 Crore (Source: CyberMedia Research, 2012). When the M&V process comes into the picture, clients and financers will have more confidence in performance contracting as they would have an independent, third party verifier to determine the achievable savings.

- Demand Side Management (DSM): Water supply and street lighting systems generally take away around 50% to 60% of the total budget of municipalities. In the recent past we have seen municipal corporations float RFPs for street light and water pump projects but either these RFPs are later scrapped or not properly implemented. The main issues behind this remain the same (baseline measurement, M&V and trust factor between parties). M&V process will help in proper implementation of these projects by building trust via a third party verifier of actual savings achieved.

Agricultural sector uses around 20% of the total national consumption of electricity. Electricity utilities provide farmers with subsidies of about Rs 42,000 Crore annually. Around 20 million inefficient pumps make the situation worse. BEE has plans to involve private players to replace theses pumps with energy efficient pumps in different phases. M&V process can be a link between pump manufacturers and electricity utilities to determine the efficiency of pumps in terms of energy savings. This process will help all three parties: farmers to get an efficient pump, pump manufacturers to get back the investment by sharing the savings and utilities to reduce the consumption of highly subsidized electricity.

- ISO 50001: Implementation of M&V processes is also a pre-requisite forISO 50001 certification for organizations. Any organization that wishes to beISO 50001 certified must have an energy management system in place that commits to the reduction of energy consumption by a specified percentage. Adoption of M&V processes helps in determining the energy savings achieved.

Future of M&V in India: In later phases of the PAT regime, it is possible that the government will come up with mandatory energy audits for industrial units to setup a baseline for their energy consumption. In such a scenario, the M&V process will also help in bringing down manufacturing costs, as energy consumption per unit of output will go down.

The concept of M&V is still quite new and only a few professionals are M&V certified inIndia, currently. Countries such as theUSA,Canada,China,SpainandFranceare following M&V regimes for a long time and we need to learn from their experience. As M&V is an evolving process, it is a must thatIndiaand Indian professionals must be updated on the latest technologies and methodologies around the world.

In India AEEE (Alliance for an Energy Efficient Economy), a non-profit organization has joined hands with EVO (Efficiency Valuation Organization) of United Kingdom to promote awareness and adoption of M&V processes and ISO 50001 certification. To know more about AEEE and their upcoming events on M&V, please log on to http://www.aeee.in/.